Fixon Laser CW Fiber Series — built to fix the real problems in welding

- One platform, all your welds: Broad power range with both single-mode and multi-mode options. Use single-mode for ultra-fine seams and thin gauges; switch to multi-mode for deeper, wider fusion on thicker parts—no need to change systems.

- Stable beams that hold your spec: High stability across the full power range keeps penetration and seam width consistent, cutting scrap, rework, and inspection headaches.

- Runs long, runs cool: Extremely long pump diode lifetime and water-cooling for 24/7 duty. Choose an integrated chiller or a standalone unit to fit your cell layout.

- Plug into your workflow: Available with multiple fiber terminations, collimation optics, and processing heads, so integration with robots, gantries, or handheld stations is straightforward.

- Lower energy, lower cost: High wall‑plug efficiency reduces power consumption while delivering the output you need—better throughput, cleaner bottom line.

If you’re fighting spatter, heat distortion, or inconsistent seams—especially on aluminum, stainless, and thin sheet—Fixon Laser CW Fiber gives you a stable, predictable process that hits spec and keeps the line moving.

Features

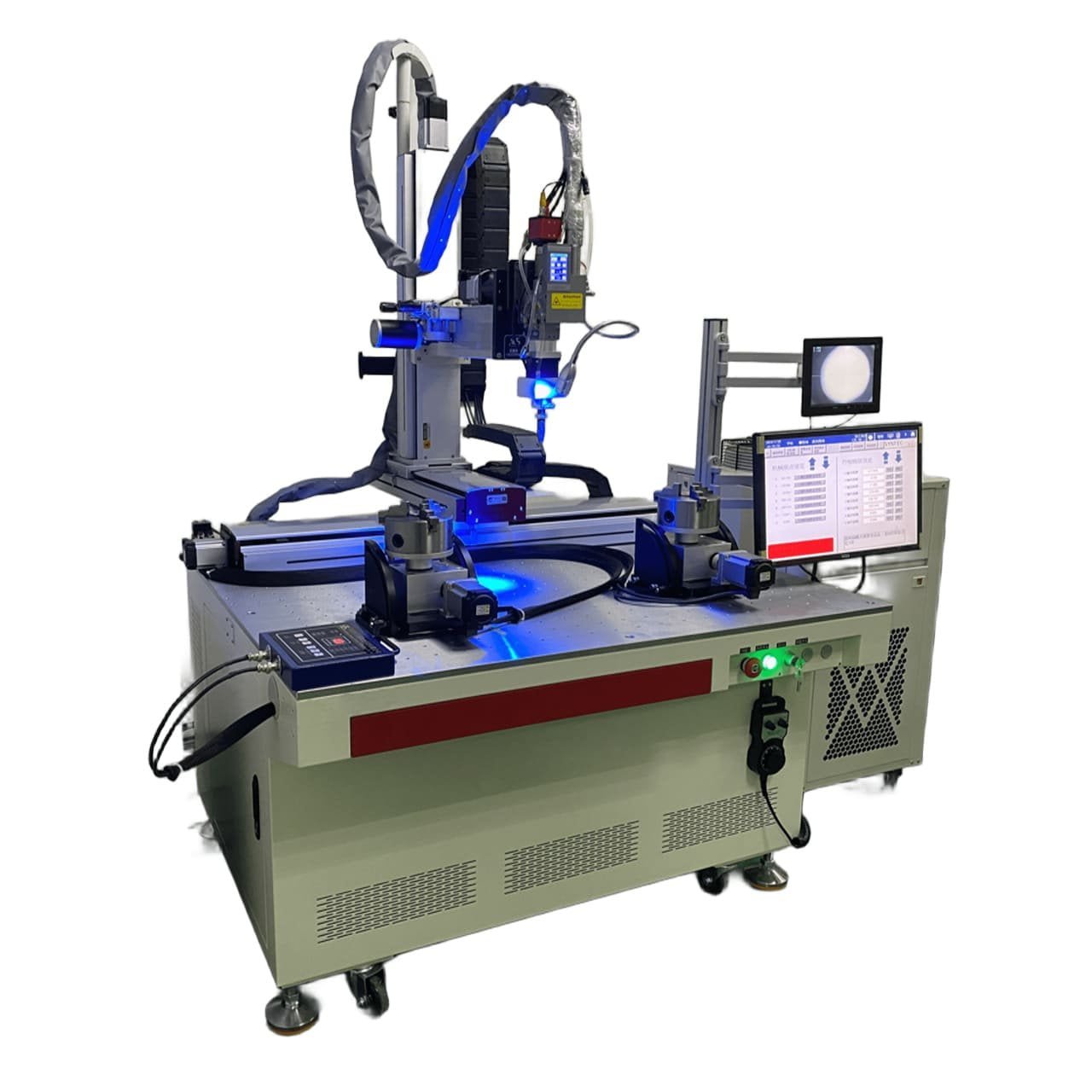

Fixon Laser 5‑Axis Robotic Welding — engineered to crush the real pain points on your line

- Energy that doesn’t drift: Our energy closed-loop (negative feedback) control keeps laser output rock-solid. Real-time monitoring with automatic compensation ensures consistent heat input and uniform penetration, shift after shift.

- High yield on complex parts: The 5-axis high‑precision robot moves the laser head freely in space, making alignment easy. With simple fixtures, you can nail difficult, special-shaped welds without trial-and-error.

- Weld more, worry less: Handles a wide range of materials—including dissimilar metals—while maintaining clean seams and low spatter.

- Built for speed and integration: High automation compatibility and high-speed welding for fast takt times, seamless with your robots, vision, and MES.

- One laser, many points: Use optical switching and fiber distribution to route the beam to multiple stations—simultaneously or time-shared—to maximize machine utilization.

- Smarter stations, faster turns: Configure multiple workstations for parallel loading/unloading to keep the arc-on time high and the bottlenecks low.

Parameter

| Model No. | HLY-AC2000 | HLY-AC3000 |

| Max focal diameter | ≤5mm | |

| Fiber cable core diameter | 50um | |

| Water temperature | 20-25℃ | |

| Temperature of working environment | 10-35℃ | |

| Humidity of working environment | ≦95% | |

| Cooling System | Water Cooling | |

Application

Fixon Laser — built to solve real welding headaches

- Core applications: Precision welding of sheet metal, stainless steel, and aluminum alloys.

- Industries served: Automotive, aviation, aerospace, shipbuilding, power battery packs, hardware, and kitchenware.

- Why it works: Stable energy delivery, clean seams, low distortion—especially on thin gauges and high-reflectivity materials.

Hot tags: 6‑Axis Robotic Fiber Laser Welding Machine, China 6‑Axis Robotic Fiber Laser Welding Machine manufacturer, factory supplier.