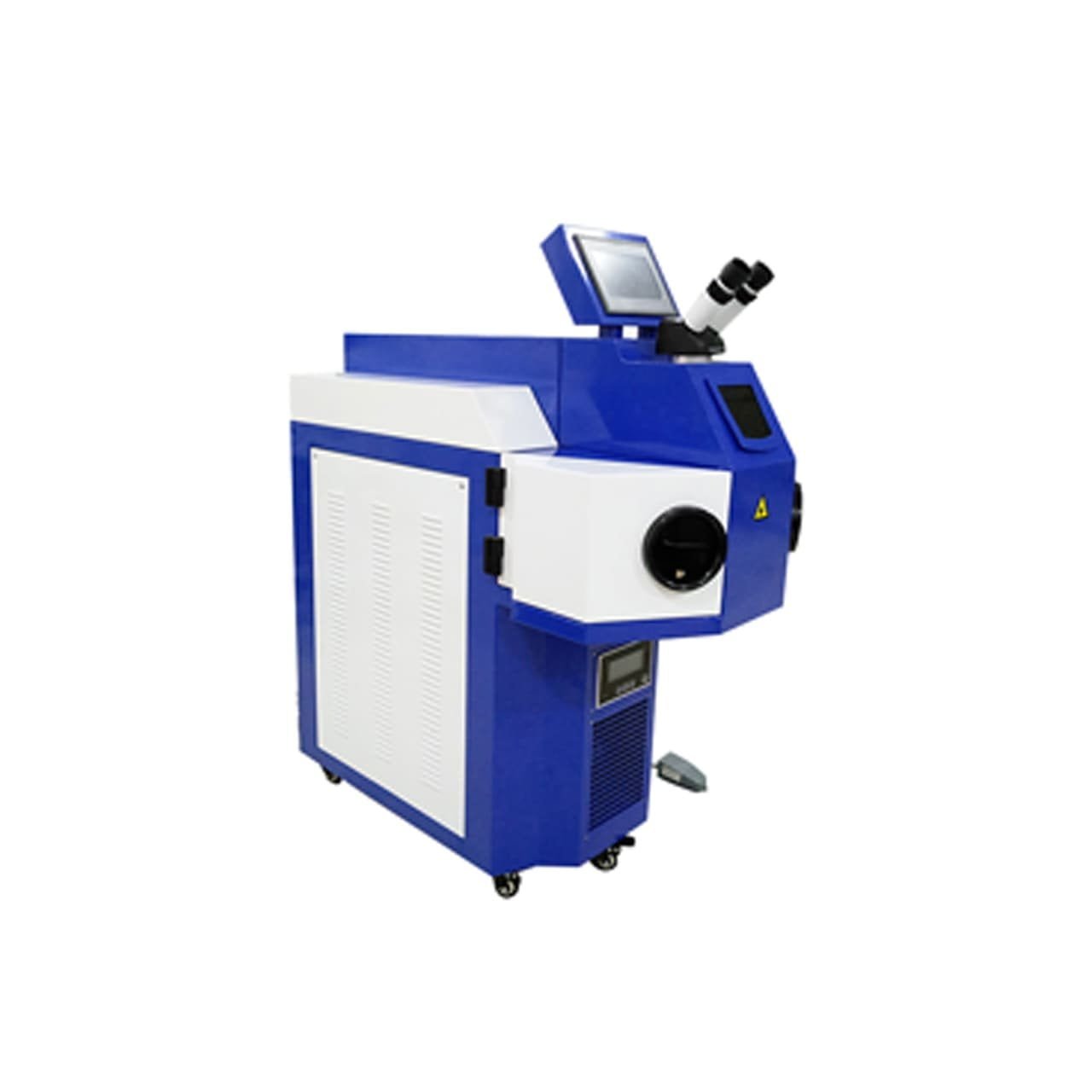

Laser spot welder advantages for jewelry and dental repair:

Compact, all-in-one workstation: integrated glove box keeps the work area clean and stable, ideal for delicate pieces and intraoral appliances.

Precision targeting: microscope with coaxial focus and aiming ensures you hit the exact spot—no overrun, no rework.

Eye-safe, fatigue-free operation: LCD light valve plus full eye protection delivers clear vision without glare, even during long sessions.

Consistent, pinpoint welds: perfect for prong repairs, chain links, bezel adjustments, and micro-welds on dental clasps and frameworks.

Minimal heat impact: protects gemstones, preserves metal finish, and prevents distortion of dental alloys.

Faster turnaround, less polishing: smooth seams reduce post-processing and keep the original shine of precious metals.

Industry Challenges & Opportunities

Jewelry Industry Challenges:

• Manual welding often leaves rough, uneven seams.

• Heat can discolor surfaces and dull the natural luster of precious metals.

Dental Industry Challenges:

• The heat-affected zone can distort dental alloys and compromise fit.

• Achieving tiny, highly precise welds is difficult with conventional methods.

Opportunities with Laser Spot Welding:

• Ultra-precise micro-welds with pinpoint control.

• Smooth, clean seams that minimize post-processing.

• Preserves the original shine and integrity of precious metals.

Parameter

| Model No. | HLY-W150 | HLY-W200 |

| Max pulse energy | 120J | 140J |

| Pulse energy | ≤20Hz | |

| Pulse width | 0.1-20ms | |

| Focal diameter | 0.1-2.0mm | |

| Rated power | ≤5kW | ≤6kW |

| Power supply | AC220V/50Hz(60Hz is optional)/AC110V 50/60Hz | |

| Control system | Microchip CPU | |

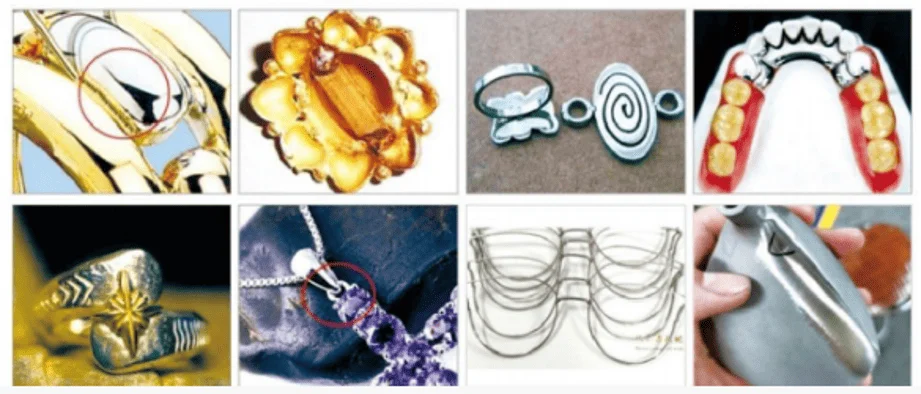

Application and Cases

Jewelry Repair:

• Gold ring crack repair (before & after)

• Chain welding with invisible seams

Dental Welding:

• Cobalt-chrome dental framework welding

• Bridge connections, precise and strong