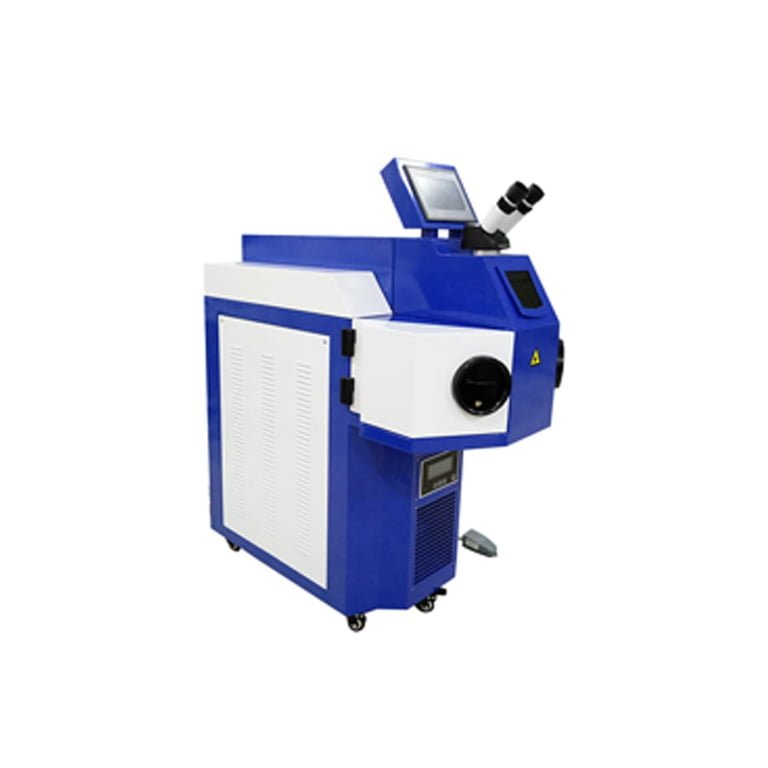

Laser deposition welding—built for mold makers who demand precision and speed.

Purpose-built for the mold industry: Ideal for repairing precision molds used in digital products, mobile phones, toys, automotive, motorcycles, and broader molding applications.

Repair to reuse: Restore worn or damaged molds, cut production costs, and boost efficiency—faster turnaround, less scrap.

Agile redesign: Modify mold design or dimensions on the fly, shortening development cycles and accelerating time to market.

Clean, precise, and reliable—get more life out of every mold.

Parameter

| Model Type | HLY-WD200 | HLY-WD300 | HLY-WD400 |

| Pulse energy | 100J | ||

| Pulse frequency | ≤100Hz | ||

| Pulse width | 0.1-20ms | ||

| Focal diameter | 0.1-1.5mm | 0.1-2.0mm | 0.1-2.0mm |

| Power consumption | ≤6KW | ≤8KW | ≤9KW |

| Power supply | AC220V/50Hz | AC380V/50Hz/3Phase | |

| Control system | Microchip CPU | ||

Application and Cases

Suitable materials

A wide range of metals can be welded with confidence: cold-work alloy steel, hot-work alloy steel, nickel tool steel, high-grade steel, steel alloys, and high-tenacity aluminum alloys, among others.