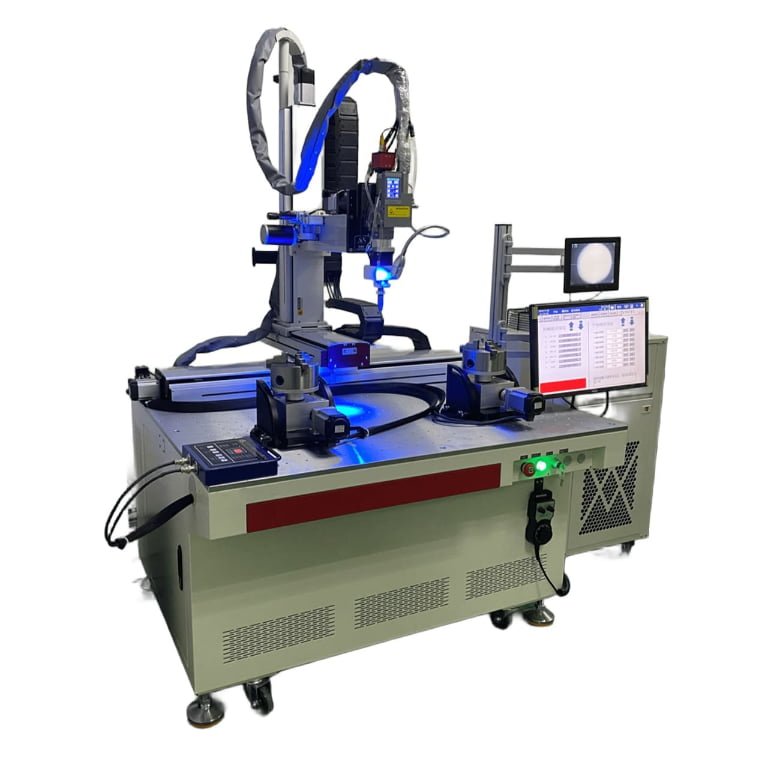

Fixon Laser CW fiber solutions for stable, high-quality welding:

Rock-solid beam stability: Continuous-wave fiber lasers suppress focal drift caused by thermal lensing and mode changes, delivering consistent energy at the weld and visibly improving seam quality and process stability.

Built for the production line: A robust mechanical design with a solid metal outer shell resists impact, dust, vibration, and wide temperature swings—ideal for 24/7 industrial environments.

Fully integrated fiber architecture: Unlike traditional solid-state lasers with rods, lenses, and multiple alignments, Fixon’s fiber laser integrates the resonator inside the fiber itself. Several meters of doped fiber replace the laser rod, and optics are simplified into fiber components.

Zero fuss setup: No para-positioning, no post-installation calibration, no lens surface cleaning. You get faster commissioning, fewer variables, and minimal maintenance—often close to zero.

Consistent uptime, lower cost of ownership: Fewer optical components mean fewer failure points, better repeatability, and reduced service visits—all translating into stable production and a cleaner bottom line.

Features

Fixon Laser CW fiber solutions that solve real welding pain points:

- Power and wavelength coverage that match your jobs: From fine micro-welds to deep penetration, choose single-mode for razor-sharp seams or multi-mode for robust energy delivery—without juggling multiple machines.

- Beam that doesn’t wander: Negligible beam pointing and stable mode quality across the full power range mean your weld stays exactly where you set it, reducing scrap and rework.

- True single-mode precision: Excellent beam quality gives tight focus and clean, narrow seams—ideal for thin materials, intricate joints, and high-reflectivity metals.

- Direct kHz modulation: Fast, precise heat input control to tame spatter, minimize HAZ, and dial in repeatability for spot, stitch, and contour welds.

- Record-level wall-plug efficiency: More output per watt in, cutting energy bills and enabling higher duty cycles without thermal headaches.

- Built for uptime: Extremely long pump diode lifetime and maintenance-free operation keep your line running—no lens cleaning, no constant realignment.

- Cooling that fits your floor: Water-cooled units available with integrated or standalone chillers, so you can drop into existing cells or build new stations with minimal hassle.

- Ready for your tooling: A wide selection of fiber terminations, collimators, and processing heads, so integration with robots, gantries, and hand stations is plug-and-play.

- Reliability you can bank on: Industrial-grade design delivers consistent performance shift after shift, with very low total cost of ownership.

If your current welding setup struggles with unstable seams, heat distortion, or frequent maintenance, Fixon Laser CW fiber systems give you stable beams, precise control, and worry-free operation—so you hit spec, ship faster, and spend less.

Parameter

| Model No. | HLY-CW1000 | HLY-CW2000 | HLY-CW3000 |

| Laser model | Multi-mode | ||

| Max focal diameter | ≤5mm | ||

| Fiber cable | 10m | ||

| Fiber cable core diameter | 50um | ||

| Control System | AD | ||

| Water temperature | 20-25℃ | ||

| Power supply | AC 220V±10%,50/60Hz | ||

| Temperature of working environment | 10-35℃ | ||

| Humidity of working environment | ≦95% | ||

| Cooling System |

Water Cooling | ||

Application and Cases

Fixon Laser CW fiber welding—built for real-world production:

- Core applications: Precision welding of sheet metal, steel, stainless, and aluminum alloys.

- Industries served: Automotive, aviation, aerospace, shipbuilding, power battery packs, hardware, and kitchenware.

- Why it works: Clean seams, low heat input, and stable beams that hold spec on thin gauges and high-reflectivity materials—without warping, burn-through, or endless rework.

If your line demands consistent penetration, tight aesthetics, and fast takt times, Fixon Laser keeps the welds crisp and the throughput high.